| 1 |

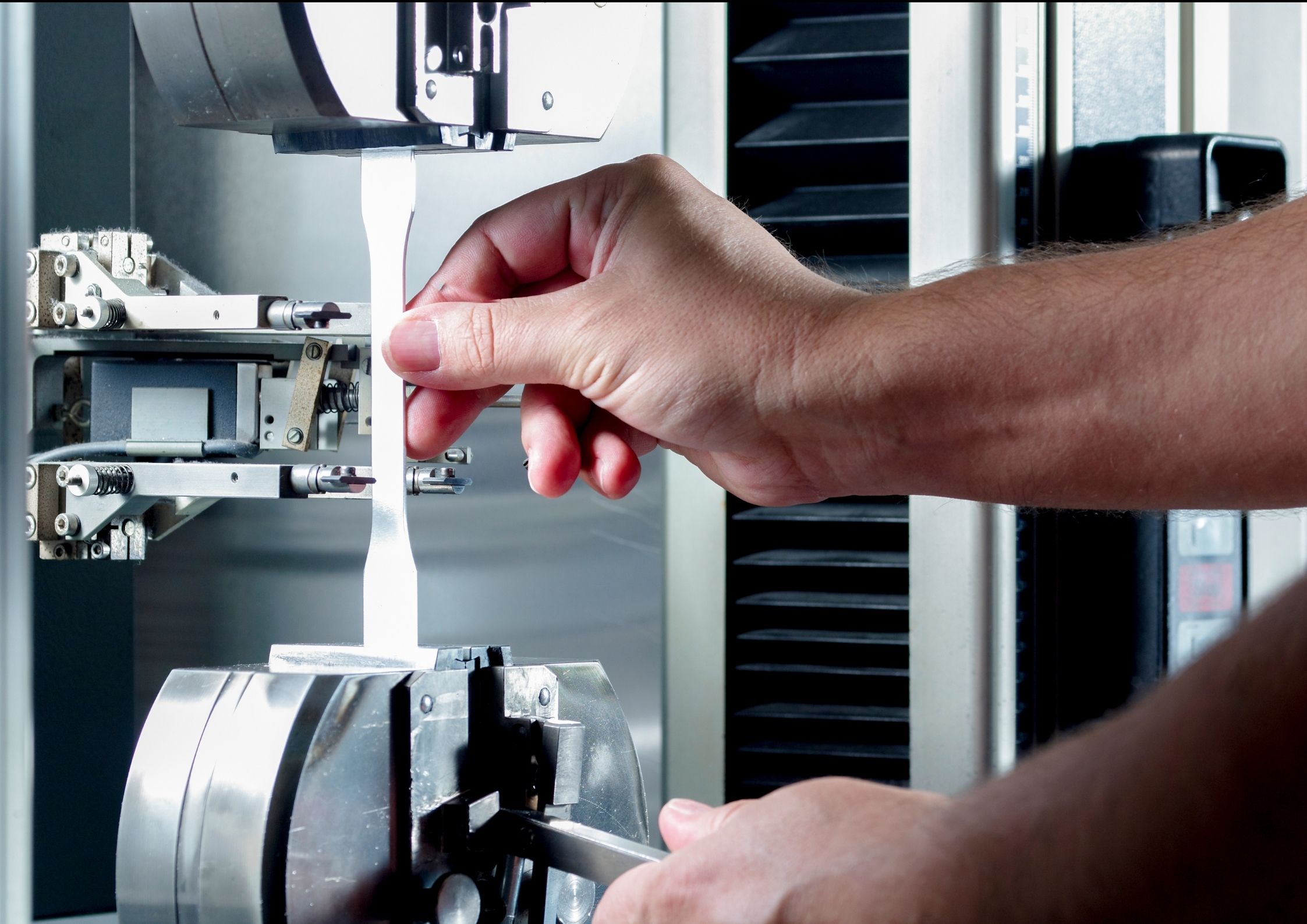

Central Manufacturing Technology Institute (CMTI), Bengaluru |

To jointly work on R&D in Design and Manufacturing Engineering and also in areas like Micromachining, Green Manufacturing, Smart Manufacturing, Industrial Ergonomics, Additive Manufacturing, Welding, Machining, Finishing, Metrology and other Advanced Manufacturing Technology areas. |

Read

More |

| 2 |

SkillDzire Technologies Private Limited, Hyderabad, |

To jointly work on imparting knowledge by conducting workshops, FDPs, internships, job-oriented trainings, placements, real time projects and industry training and provide placements to the deserving candidates. |

Read

More |

| 3 |

Cadmaxx Solutions Education Trust,

Bengaluru |

The purpose of this Agreement is to promote collaboration in engineering education and problem-solving activities between the Department of Mechanical Engineering of Atria Institute of Technology and Cadmaxx Solutions Education Trust. |

Read

More |

| 4 |

LGS Trust,

Bengaluru |

Implementation of AICTE Activity Points as per the rules set by AICTE and VTU for the students of 2nd Party completely on online via the website www.lgstrust.com. Timeline to achieve the goal depends on the student involvement with the project. However as per our analysis, a project for 20 points can be completed within 10 to 15 days. There are no limitations on the registration. Our site will be up 24/7 allowing students to register at any time. Site is developed in such a way that students need not to wait for the instructor. They can continue their task at any time at their convenience. However it is advisable to follow the instructions of their department and VTU |

Read

More |

| 5 |

Prinston Smart Engineers,

Bengaluru |

The Memorandum of Understanding is made between Department of Mechanical Engineering, ATRIA Institute of Technology and PRINSTON SMART ENGINEERS, to promote the cooperation in Workshops, Conferences and Seminars/webinars would be mutually beneficial. The areas of cooperation may include, subject to mutual consent, any deniable and foamble activity that would further the goals of each institution. Such interaction may include cooperation in a variety of joint academic and educational activities. |

Read

More |

| 6 |

Vocuni Private Limited,

Bengaluru |

The purpose of this Agreement is to promote collaboration in engineering education and problem-solving activities between the Department of Mechanical Engineering of Atria Institute of Technology and Vocuni Private limited 2C 202 2nd cross 3rd Block H.R.B.R. Layout St Thomas Town, Bengaluru, Karnataka, India 560084 |

Read

More |

| 7 |

Square Edge,

Bengaluru |

The Memorandum of Understanding is made between Department of Mechanical Engineering, ATRIA Institute of Technology and PRINSTON SMART ENGINEERS, to give the training on latest skill which is required current technology like Catia, Cadd Naxt, Solid works |

Read

More |

| 8 |

Society of Automative Engineers ,

India |

To enhance the knowledge base of student members about recent trends in the engineering of mobility systems To benefit its student members and faculty with knowledge of the latest advancements in technology in the field of automobiles To provide to its members access to SAE International programs and services globally enabling them to practice world class standard in productivity and quality To provide a forum for members to informally exchange views and ideas |

Read

More |

| 9 |

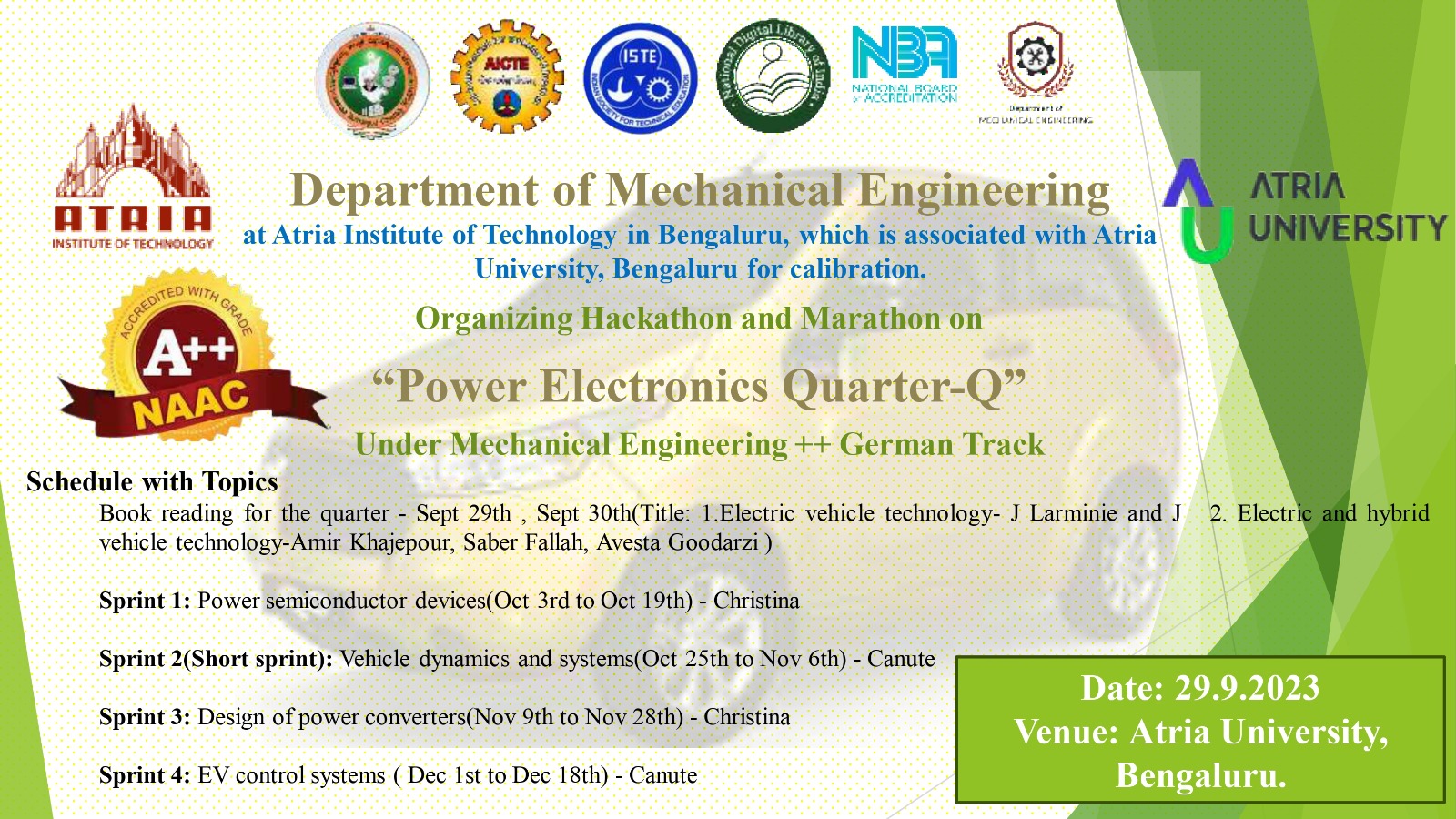

Hypotech Hydraulics Pvt. Ltd., Bengaluru ,

India |

The main objective of the MoU is Development of Job-Ready Manpower for the

Manufacturing Sector, Technology Transfer & Knowledge Upgradation, Research Capability

Enhancement of AIT Faculty, Opportunities for Qualification Enhancement of Hypotech

Hydraulics Pvt Ltd Employee and Development of Capabilities and Institutionalized

Platforms for Futuristic Requirements. |

Read

More |

| 10 |

Silicon Micro Systems, Bengaluru

India |

The main objective of the MoU is Collaborative Work for Digital Manufacturing and

Additive Manufacturing, Utilizing SILICON MICROSYSTEMS Facilities for experimental

work, Joint Research Activities, Sponsorship for PhD Programs, Offering UG Projects. |

Read

More |

| 11 |

Medini Technologies,Bengaluru

India |

The main objective of the MoU is Collaborative Work for Design and Analysis of

components and Utilizing SILICON MICROSYSTEMS Facilities for experimental work,

Joint Research Activities, Sponsorship for PhD Programs, Offering UG Projects. |

Read

More |